Slip Bowls

3.5″/150K High Capacity Slip Bowl

Specifications

- Rated load: 150,000 lbs.

- Designed and tested in compliance with API-8C (factor-of-safety rating 1.5:1)

- Cast carriers with replaceable dovetail slide plates

- Overall dimensions: 16-1/2” wide x 18” length x 16” high

- Weight: approx. 315 lbs. less inserts

- Stationary mounting: 2 ea. 1-1/8” holes @ 180 deg. on 13-1/4” DBC

- Traveling bowl mount pattern: 1-1/8” tie rod hole pattern: 4 ea. equally spaced on 14” DBC (approx. 9.9” x 9.9”)

- Gate pin dims: 2” diameter

- Insert max: 3-1/2” diameter

- Tie rod size: 1-1/8” diameter

- Gate opening: 6-1/4”

- Max open dia. less inserts: 5-3/8”

- Normal operating pressure: 600-1500 psi

- Cross port relief valve

- Hose connections: 3/4” quick disconnects

- Proof load tested to 1-1/2 times max load rating (225,000 lbs.).

- Critical parts will be NDE inspected after testing.

- Slip bowls will be stamped and numbered per customer request.

- Slip bowls will be sandblasted; zinc primered, and painted black. Custom color may be requested for an additional charge.

- Top plate machined to accept (optional) guide rings.

Optional Components

- Optional guide rings

- Optional pipe inserts (pipe dies)

5.5″/225K High Capacity Slip Bowl

Specifications

- Rated load: 225,000 lbs.

- Designed and tested in compliance with API-8C, with factor-of-safety rating of 1.5:1

- Cast carriers with keyway slots

- Full opening

- Overall dimensions: 22” wide x 21” length x 18-3/8” high

- Weight: approx. 550 lbs. less inserts

- Traveling bowl mount pattern: 1-1/8” tie rod hole pattern: 4 ea. equally spaced on 14” DBC (approx. 9.9” x 9.9”)

- Gate pin dims: 13-1/8” center to center of gate pins

- Insert max: 5-1/2” diameter

- Tie rod size: 1-1/8” diameter

- Gate opening: 6-5/8”

- Max open dia. less inserts: 8-3/8”

- Normal operating pressure: 600-1500 psi

- Cross port relief valve

- Hose connections: 3/4” quick disconnects

- Proof load tested to 1-1/2 times max load rating (337,500 lbs.).

- Critical parts will be NDE inspected after testing.

- Slip bowls will be stamped and numbered per customer request.

- Slip bowls will be sandblasted; zinc primered, and painted black. Custom color may be requested for an additional charge.

- Top plate machined to accept (optional) guide rings.

Optional Components

- Optional two piece guide rings

- Optional insert adapters (piggybacks) for smaller pipe sizes

- Optional pipe inserts (pipe dies)

7.06″/300K Full Bore Slip Bowl

Specifications

- Rated load: 300,000 lbs.

- Designed and tested in compliance with API-8C (factor-of-safety rating 3:1)

- Cast carriers with replaceable slide plates

- Overall dimensions: 14” wide x 19-1/2” length x 18-1/4” high

- Weight: approx. 480 lbs. less inserts

- Stationary mounting: 2 ea. 1” bolts @ 180 deg. on 16-1/4” BC

- Traveling bowl mount pattern: 1-1/8” tie rod hole pattern: 4 ea. equally spaced on 14” DBC (approx. 9.9” x 9.9”)

- Standard insert max: 3-1/2” diameter

- Custom insert max: up to 5-1/2” diameter

- Tie rod size: 1-1/8” diameter

- Max open dia.: 7-1/16”

- Normal operating pressure: 600-1500 psi

- Hose connections: 3/4” quick disconnects

- Proof load tested to 1-1/2 times max load rating (450,000 lbs.)

- Critical parts will be (NDE) inspected after testing.

- Slip bowls will be stamped and numbered per customer request.

- Slip bowls will be sandblasted; zinc primered, and painted black. Custom color may be requested for an additional charge.

- Top plate machined to accept (optional) guide rings.

Optional Components

- Optional two piece guide rings

- Optional pipe inserts (pipe dies)

7.63″/340K High Capacity Slip Bowl

Specifications

- Rated load: 340,000 lbs.

- Designed and tested in compliance with API-8C, with factor-of-safety rating of 1.5:1

- Cast carriers with keyway slots

- Standard opening (not full opening)

- 2 ea. swivel lift eyes (for handling)

- Overall dimensions: 24-1/2” wide x 22-13/16” long x 23-3/4” high

- Weight: approx. 1082 lbs. less inserts

- Tie rod hole pattern: 18-1/16” width x 10-3/4” length

- Gate pin dims: 13-11/16” center to center of gate pins

- Insert max: 7-5/8” diameter

- Tie rod size: 1-1/4” diameter

- Gate opening: 9-3/16”

- Max opening less inserts: 9-13/16”

- Normal operating pressure: 600-1500 psi

- Cross port relief valve

- Hose connections: 3/4” quick disconnects

- Proof load tested to 1.75 times max load rating (595,000 lbs.).

- Critical parts will be NDE inspected after load testing.

- Slip bowls will be stamped and numbered per customer request.

- Slip bowls will be sandblasted; zinc primered, and painted black. Custom color may be requested for an additional charge.

- Top plate machined to accept (optional) guide rings.

Optional Components

- Optional two piece guide rings

- Optional insert adapters (piggybacks) for smaller pipe sizes

- Optional pipe inserts (pipe dies)

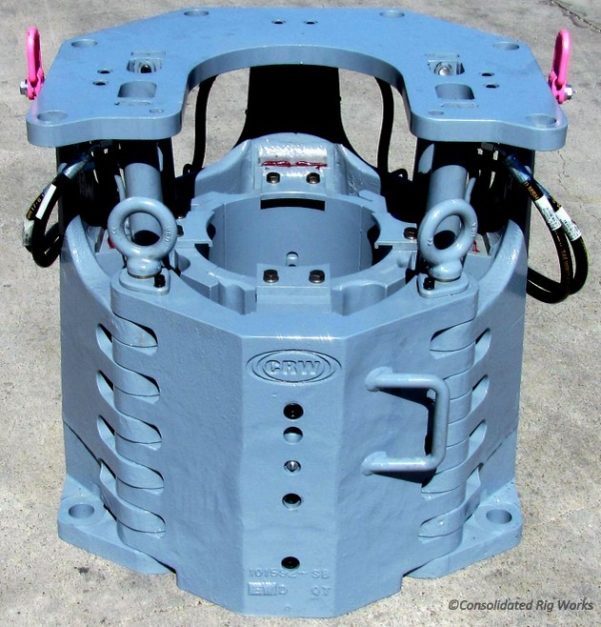

9.63″/600K High Capacity Slip Bowl

Specifications

- Rated load: 600,000 lbs.

- Designed and tested per API-8C with an improved factor-of-safety rating of 2.67:1.

- Cast gate and housing

- Cast carriers with keyway slots

- Standard opening. (not full opening)

- 2 ea. swivel lift eyes. (for handling)

- Overall dimensions: 28” wide x 28” deep x 26‐5/8” tall

- Weight: approx.: 2,000 lbs. less inserts

- Mounting bolt hole pattern: 12‐1/2” x 25‐1/4” rect. + 2 holes at 12.63 x 12.5

- Mounting bolt dia. 1‐1/2”

- Tie rods must be used in traveling snubbing operations.

- Gate pin diameter: 1‐3/4”

- Tubing size range: 7-5/8” and 9-5/8”

- Tubing size range: with optional insert adapters: 2-3/8” thru 7-5/8”

- Max opening with inserts: 11-13/16”

- Max opening without inserts: 12-3/16”

- Normal operating pressure: 600‐1500 psi

- Cross port relief valve

- Hose connections: 3/4” quick disconnects

- Proof load tested to 1.5 times max load rating (900,000 lbs.)

- Critical parts NDE inspected after testing

- Slip bowls will be stamped and numbered per customer request

- Slip bowls will be sandblasted; zinc primered, and painted black. Custom color may be requested for an additional charge.

- Top plate machined to accept (optional) guide rings.

Optional Components

- Optional two piece guide rings

- Optional insert adapters (piggybacks) for smaller pipe sizes

- Optional pipe inserts (pipe dies)

NOTES ON CRW SLIP BOWLS:

- CRW slip bowls are engineered to have an improved safety factor rating.

- CRW slip bowls are designed to be in compliance with API-8C, with exceptions.

- CRW slip bowls are delivered with complete material traceability data books.

- CRW issues a Certificate of Compliance (COC) for each slip bowl that states the compliance to API-8C and all associated exceptions.

- CRW slip bowl designs undergo an independent design review by Bureau Veritas (BV) and have an associated Independent Review Certificate (IRC) issued by (BV).

- CRW slip bowls are proof loaded and completely function tested prior to shipment.

- Each slip bowl is certified to be sound through MAG-particle inspection after being proof loaded.